Electrical Submersible Pumps (ESPs) have become a cornerstone of oil and gas extraction, changing the means fluids are moved from below ground tanks to the surface. As the worldwide demand for power remains to rise, the efficiency and integrity of ESP systems are progressively vital. This has actually spurred substantial developments in ESP parts and components, making sure that operators have accessibility to high-quality equipment that can withstand the harsh atmospheres often come across in oilfield operations. The ESP parts offered today are designed to improve the efficiency and longevity of these systems, and recognizing these components is crucial for ideal operational effectiveness.

Among one of the most vital aspects of ESP systems is their individual components, that include motors, pumps, cords, and control systems. Each part plays a critical role in the overall functionality of the ESP setup. As an example, the motor is accountable for driving the pump, converting electrical energy into mechanical energy that moves the fluid upwards. Selecting high-quality ESP motor parts is essential for making certain that the pump runs at maximum effectiveness. Robust style and building and construction of the electric motor ensure it can sustain long term direct exposure to particular oilfield conditions, including temperature level variants and destructive settings.

In enhancement to the motor, numerous ESP components add to the fluid transportation mechanism. The pump itself is crafted to deal with specific circulation rates and fluid kinds while offering an optimal training capacity. The selection of materials comes to be critical in making certain that the pump can withstand wear and tear created by corrosive chemicals or unpleasant fluids frequently existing in oil and gas extraction. Picking oilfield ESP parts produced to rigorous criteria aids decrease the threat of unexpected downtimes due to equipment failure, therefore conserving time and improving efficiency.

An additional crucial element of the ESP system is the wire, which attaches the motor to the power supply. These cables should be durable and flexible, standing up to rough ecological conditions such as heats, pressures, and exposure to chemicals. High-quality ESP cables also improve energy performance, ensuring that maximum power is supplied to the electric motor without substantial losses. This can have a straight effect on functional expenses, as better energy performance converts right into lower power usage and decreased overall expenses.

Control systems are crucial in modern ESP arrangements, supplying real-time monitoring and functional administration of the pump. With the arrival of electronic technology, drivers can currently use innovative control systems that provide information on performance metrics, enabling proactive upkeep and further optimization of procedures. By including high-quality ESP components that sync perfectly with these control systems, drivers can ensure that their equipment works efficiently, reducing downtime and boosting the integrity of the entire system.

The value of submersible pump accessories need to not be overlooked. Accessories such as sensing units, Electrical Submersible Pump Oil and Gas Industries guards, and connectors play a significant function in making sure the reliable and secure operation of the entire ESP system. Protectors guard against problems such as motor overheating, while sensing units supply important information pertaining to liquid degrees and temperature level. These accessories can greatly influence the operational lifecycle of an ESP installation, using crucial responses that aids drivers make educated choices to reduce possible concerns prior to they rise.

In the context of the oil and gas industries, sourcing high-quality ESP parts is critical for sustainability and effectiveness. Not just do high-quality components aid maintain the stability of the whole manufacturing process, but they additionally contribute to overall environmental duty.

Furthermore, investing in high-quality ESP parts and components commonly confirms to be more affordable in the lengthy run. While initially, the expense of premium parts may seem intimidating, the reliability and performance they provide can considerably reduce the frequency of downtime. Frequent failures due to substandard components can bring about pricey manufacturing replacements, stops, and repair services. Spending in high-quality ESP equipment assists operators strike an equilibrium between performance and cost-effectiveness, leading to greater returns on investment.

Along with traditional ESP parts, the market is seeing the combination of wise modern technologies made to boost functional management. This forward-thinking approach to ESP performance not only boosts efficiency but also lines up with the market's moving focus toward sustainable practices.

As energy needs raise and areas age, drivers must prioritize the top quality of their ESP components to ensure the durability and integrity of their systems. By concentrating on high-quality ESP parts, operators can position themselves for success, improving performance while minimizing expenses and ecological influences. Given the challenges dealt with within the market, it comes to be essential to work with trusted producers who can supply the ideal ESP components customized to details functional needs.

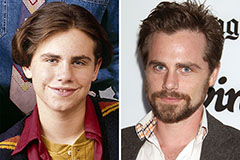

Rider Strong Then & Now!

Rider Strong Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now!